SuperVisor System (SVS)

Project Description

Process controller and supervisor for micro-generation.Project Details

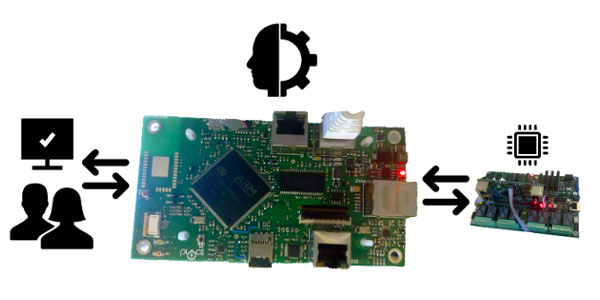

SVS is an electronic board for process supervision and control in the field of micro generation, designed to be very flexible and configurable by the customer according to the needs of the specific application.

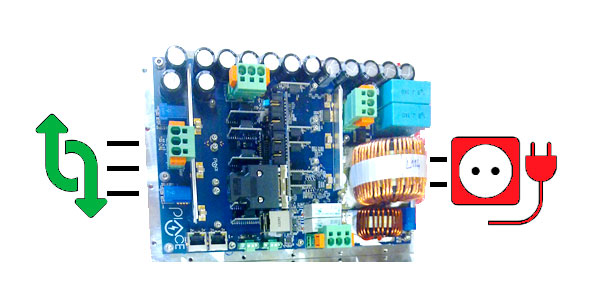

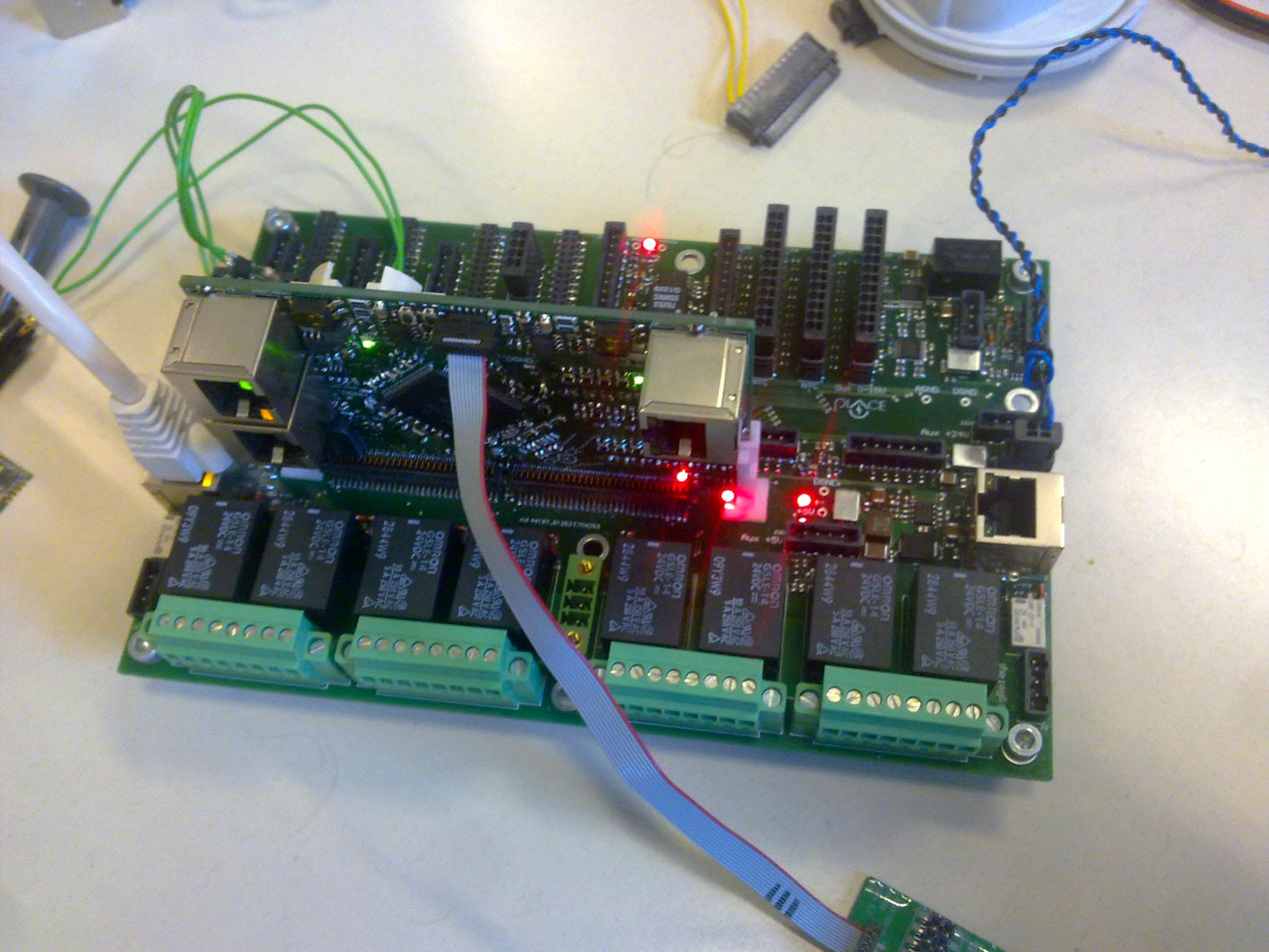

The product started as a controller and supervisor to complement the power system iPCS, especially where this is used for micro generation or co-generation in complex systems, i.e. characterized by the interaction between different sub-systems, namely electrical (such as iPCS), mechanical (e.g. internal combustion engine for co-generation), thermal (e.g. to manage the heat exchange) and fluid machines (e.g. ORC). The first application dates back to the PIACE project (Industria 2015), where SVS was used to manage an integrated system for micro generation and an optimized thermal system.

The SVS module is characterized by various types of analog inputs and outputs (4-20 mA, ±10 V, temperature sensors), digital (both 5 and 24 V), can control different kinds of loads (transistor outputs, relay outputs and commands for small stepper motors, for example for driving motorized valves). Each SVS card can also be connected to two CAN buses, in order to provide external (user) access and “internal” communication, for use with other cards in the same system.

Unlike other generic process control systems, SVS has several advantages, for example:

- versatility and customization possibilities;

- computing power;

- wide availability of power outputs and advanced functions (such as stepper valve control);

- possibility of cost savings, thanks to the possibility of selectively mounting only the necessary interfaces (I/O and power);

- possibility of support by Koala Electronics for the development of algorithms, control logic and system supervision, based on the experience of complex projects already carried out.

SVS is equipped with a high-performance microcontroller, which allows complex algorithms and control sequences to be executed with guaranteed timing.

It is normally used for the coordination of a system including one or more power converters (iPCS) and at least one user interface (HMI), which together implement all the functions needed in a micro-generation plant.

Fields of Application